Important Information to Have Handy When Replacing Your Motor

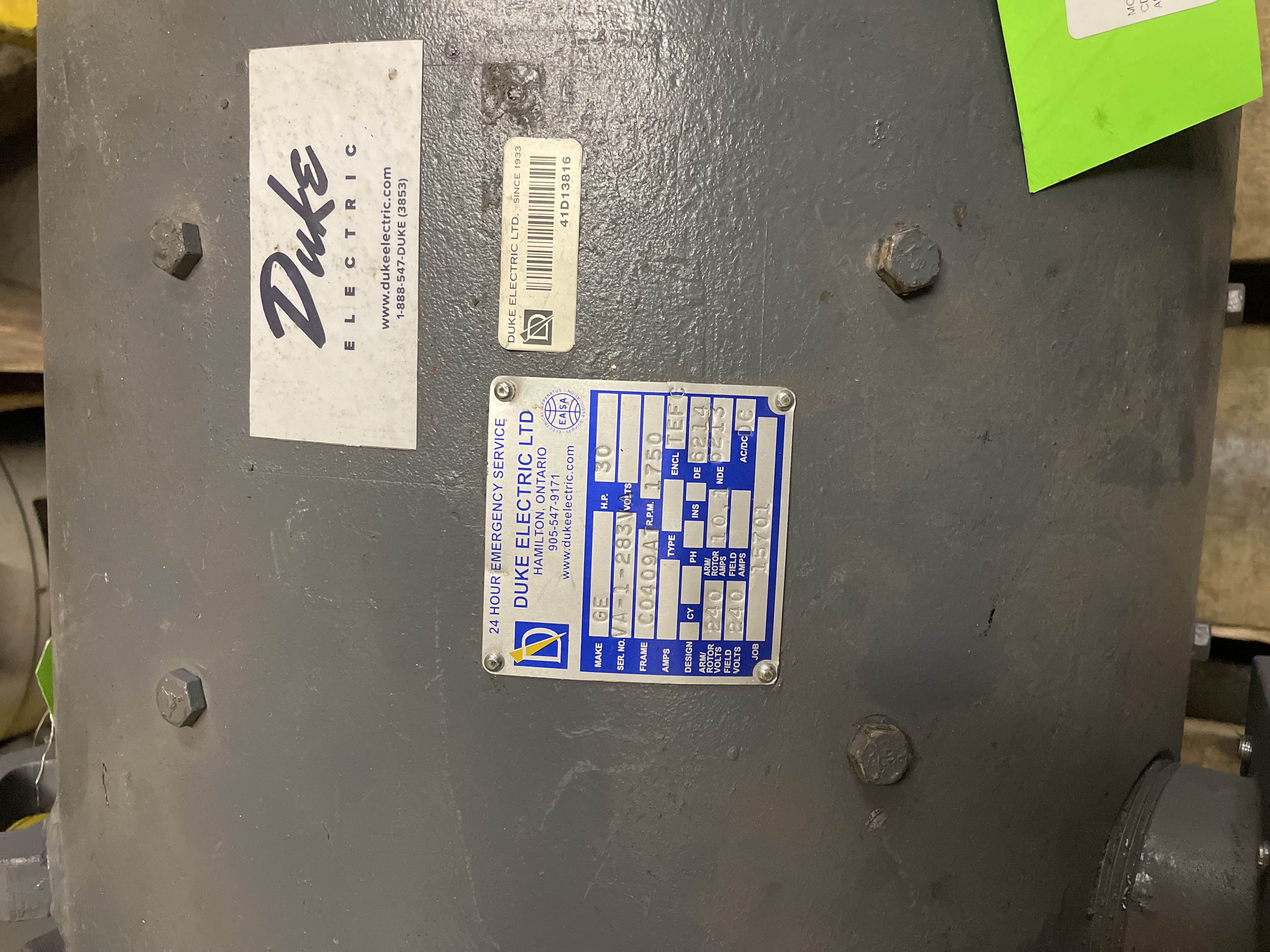

At Duke, we often get calls from customers inquiring about replacement motors without complete information. The nameplate on your motor is numero uno when it comes to the most important information to have on hand when replacing your motor.

Most times, someone will phone in looking for a replacement motor and provide only a few pieces of information. The input voltage, horsepower, and R.P.M.s are typically offered, undoubtedly important. Still, we need to have the whole picture to identify and supply you with the correct replacement motor. The easiest solution is to take a photo of the nameplate (first, perhaps try to clean it off as best you can).

Making out all the information from a picture of a nameplate is a whole other story. To get accurate information, we often have to moonlight as investigators. Cross-referencing manufacturer models and manuals mixed in with years and years of experience with motors of all kinds helps us successfully identify the right replacement motor.

What's In a Motor Nameplate?

The information on a nameplate can appear like a foreign language to most people. But it is this common language that enables installers, operators, and maintenance personnel to understand and recognize the type of motor and that motor's requirements. The nameplate defines a motor's basic mechanical design, electrical performance, and dimensional parameters.

Most nameplates are made of steel or aluminum for longevity, and the information on the plate is usually engraved for readability. The information on a nameplate is critical for installation and wiring connection, matching an appropriate speed drive, repairing, or replacing the motor.

Required or Optional Information for All NEMA Motor Nameplates

Manufacturer

Pretty straightforward. Besides the manufacturer's name, it can include the motor model, electrical style, or purpose.

Hazardous Location Classes & Groups

If the motor is required at potentially explosive or flammable sites, it's essential to select a motor that won't create an ignition source. Classes and groups are used to classify hazardous locations and how motors are rated to operate safely within them.

Frame Size (FRAME)

Motor dimension standardization is indicated by the frame size and is consistent across manufacturers. Frame size refers to mounting interfaces only.

Rated Voltage (VOLTS)

Rated voltage tells you the voltage the motor is designed to operate most efficiently. But a motor can still technically operate at plus or minus a 10 percent tolerance of this value. Performance will be affected if the motor is used at voltages other than the voltage indicated on the nameplate.

Rated Full-Load Amps (F.L. AMPS)

Full-load amps are the amount of current the motor is designed to draw at the rated load and rated voltage.

Rated Full-Load Speed (R.P.M.)

The rated full-load speed is the speed at which full load torque is delivered for the rated voltage and frequency (the difference between full load speed and synchronous speed is called slip.

Frequency (H.Z.)

Hertz is measured in cycles per second and is the input power frequency for which the motor is designed to operate. The motor frequency should match the power system (supply) frequency to operate successfully.

Service Factor (SER. F. or S.F.)

This indicates the amount of continuous overload the motor can be expected to handle without overheating or damaging the motor. Service factor can also be used to see if the motor can be operated continuously at very high altitudes satisfactorily.

Efficiency (NEMA NOM. EFF.)

Efficiency is the percentage of the input power converted to work output from the motor shaft and is calculated by dividing the output power by the input power, multiplied by 100. Efficiency is vital since the losses are paid for when the motor is running and if power costs are high or the motor runs for long periods.

Bearings (D.E. and ODE)

Usually, information is provided for the drive-end (D.E.) bearing and the bearing opposite the drive end (ODE). The numbers indicate the bearing type and size.

Certified Compliant Number (CC)

This number appears on all electric motors compliant with the NEMA Premium efficiency specification.

Serial Number (S.N.)

A unique identifier to a motor.

International Protection Rating (I.P.)

This classifies the degrees of protection provided against the intrusion of solid objects, dust, accidental contact, and water.

Enclosure Type (ENCL)

The enclosure or housing/cooling method for which the motor is designed. The enclosure by design must protect the windings, bearing and other parts from moisture, chemicals, and abrasion from grit. There are more than 20 types of enclosures.

Rated Horsepower (H.P.)

Horsepower is the motor's output rating or its ability to deliver the torque needed for the load at rated speed. In North America, we use horsepower, and in Europe, they use kilowatts.

Power Factor (P.F.)

This is the measure of a motor's requirements for magnetizing amperage.

Ambient Temperature and Time Rating (RATING)

The motor's rating is the ambient (room) temperature surrounding the motor and the length of time it can operate at that temperature. If it is not indicated, it is usually 40 degrees Celsius for IE2 motors and 60 degrees Celsius for IE3 motors.

Amps at Stated Volts

More common for smaller motors in North America.

Insulation Class (CLASS)

Expressions of the thermal tolerance of the motor winding or its ability to survive a given temperature for a given life. The higher the code letter of class, the greater the heat capacity.

Phase (P.H.)

This indicates the type of power supply for which the motor is designed. Single-phase and three-phase motors are the main categories.

Design Letter (D.E.S.)

Indicates the motor's torque characteristics or the turning force a motor develops. Starting torque is usually different from the torque required to keep the load moving. NEMA specifies design letters to indicate the three-phase induction motors' torque, slip, and starting characteristics.

Rotor Inertia

This is an object's resistance to a change in speed and is usually included for variable speed applications.

T-Code

Motors used in hazardous environments are assigned a T-code (temperature code), the max temperature of surfaces subject to contact with hazardous materials.

Safety and Efficiency Certifications

Agency marks, memberships, and testing certifications.