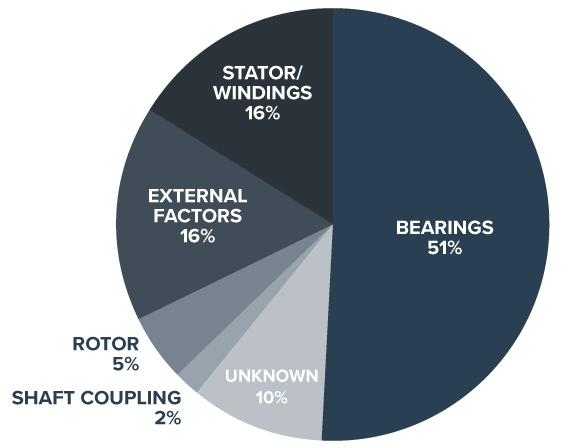

The most common causes of electric motor failure

Old equipment breaks down over time, right?

Not necessarily. While it's tempting to attribute motor failure to age, the truth is that the passage of time is responsible for less than 20% of motor failures. According to Cooper Bussmann, only about 10% of electric motor failures can be attributed to old age.

In a well-known study, A. Bonnett and C. Yung compiled survey data that identified the five most common causes of electric motor failure. These failures often stem from stresses encountered during normal operation, as well as unexpected events.

Bearings 51%

Bearings are the culprit in more than half of motor failure cases. Improper lubrication, inappropriate mechanical loads, heat, contamination and shaft currents are all the usual suspects when it comes to bearing problems. Get the bearing failure checklist.

Windings 16%

A winding failure—which is often caused by a breakdown of the winding’s insulation—will cause a short in the motor. Common causes of winding failure include high temperature, too many starts, contamination, too much current, excessive voltage and physical damage. We've put together a post on winding failure, with awesome photos courtesy of EASA, if you're looking for examples.

External Causes 16%

Tied with windings for almost 1 in 5 motor failures, external factors include temperature, contamination, poor maintenance, inappropriate mechanical loads and events such as flooding.

Unknown 10%

1 in 10 failures are mysterious. Either no one bothered to determine why the failure occurred, so Bonnett and Yung didn’t have any data to work with, or the investigation failed to determine a cause.

Rotor 5%

Starts (too many, not enough of a break between them or extended start times) are the culprit in some rotor failures. Other failures are caused by vibration, physical damage and situations that causes excessive heat.

Shafting and coupling 2%

Shaft failure is the least common cause of motor failure. Physical damage, corrosion, improper installation and excessive loads are often the root cause.

Is your motor failing?

Let us figure out the reason.