Electric Motor Buying Guide

Are you in the market for an electric motor? This guide will help you understand the different types of electric motors on the market and the various features to look for so that you can make the best-informed decision for your application.

If you’re involved in plant operations or maintenance and know you have to replace an electric motor or buy for a new application, then this guide is for you.

What you get: Choosing the right motor type, determining the application, identifying the appropriate motor size, and matching it with the industrial environment it will operate in.

In the commercial industry, electric motors are everywhere. They drive compressors and conveyors, run pumps and fans, and operate blowers, drills, and more. It’s estimated that electric motors account for nearly half of the world’s electricity consumption.

There’s been a significant shift in directing resources to manufacture and integrate more energy-efficient motors. Improving efficiency helps the environment and generates savings for the end user. So, whether you are simply buying new or replacing an old motor, it’s good to know that you’ll be promoting and benefiting from energy efficiency*.

*This applies to asynchronous A.C. electric motors, and international standards vary by country.

Did you know? Electric motors account for more than two-thirds of all energy used in any industry. Approximately half of all electricity is used by motors, which number over 700 million worldwide.

Choose your motor type

There are two general categories of electric motors: A.C. and D.C. And dammit, do we love AC/DC.

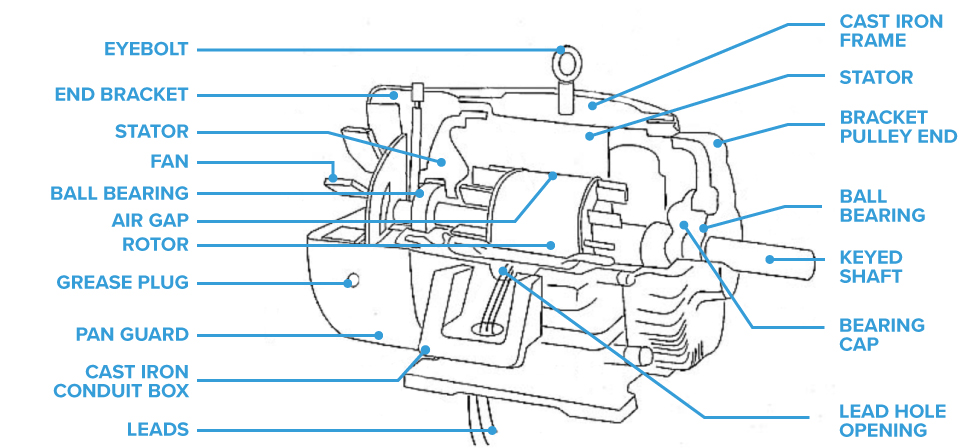

A.C. motors

A.C. (alternating current) motors convert alternating current to mechanical power. They are well-suited for applications that require continuous movement and few gear changes. They are adaptable, reliable, and used in various applications such as pumps, compressors, conveyors, machine tools, and motorized off-road equipment.

There are two types of A.C. motors:

- Single-phase motors

- Designed for smaller machines and equipment with lower horsepower requirements (think pumps, refrigerators, fans, portable drills).

- Require less maintenance and therefore often last longer

- Only one (single) phase supply to the stator

- Three-phase motors

- Used in industrial environments and electric grids, and allows more electrical power to be transmitted than single-phase

- Three-phase supply to the stator

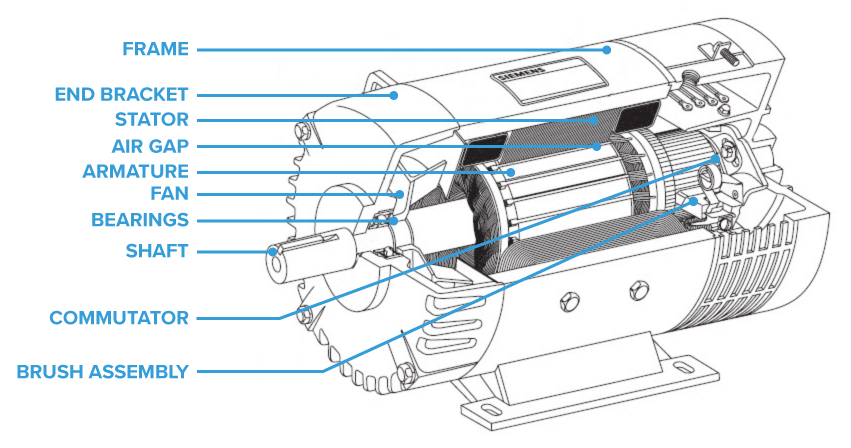

D.C. motors

D.C. (direct current) motors are also ubiquitous in industrial environments because they have advantages depending on the format, brushed or brushless. They are ideal for dynamic applications requiring a high degree of accuracy, usually in terms of speed. D.C. motors can also be great for applications requiring high power and when starting, stopping, accelerating and decelerating are needed to be done quickly.

There are two types of D.C. motors:

Brushed motors

- Simplest and most often used motors, especially when it comes to basic industrial equipment.

- They are easy to control

- They’re relatively inexpensive

- There are four types of brushed motors:

Brushless motors

- More reliable and efficient than brushed motors, as the brushes wear out more quickly, decreasing the motor’s lifespan.

- They can operate at higher speeds than brushed motors, making them ideal for grinders, fans, and saws.

- No wearing parts exist except for the bearings, which decreases maintenance requirements.

- Come with encoders (sensors) that allow for electronic switching and identification of the rotor position.

Determine the application

Selecting the correct motor for an application is rarely an easy decision. It helps to figure out fundamentals like load characteristics, horsepower, inertia, duty cycle, and motor hypoxia.

Load characteristics

Electric motor load is the current drawn by an electric motor, and it depends on the load on the shaft of a motor. It can be estimated using input power, amperage or speed of the motor.

Most electric motors run at 50-100% of the rated load, so keep that in mind. Maximum efficiency is around 75% of the rated load. Typically, motors are designed with a service factor that allows for the occasional overloading.

Loads from centrifugal pumps, fans, blowers, compressors, and similar equipment tend to be variable over time. When choosing a motor for these conditions, consider the highest continuous load point (usually at the greatest speed).

Horsepower

To determine horsepower, use a digital clamp meter to accurately measure the current and voltage of the motor and then perform the following calculation:

Horsepower (hp) = Voltage x Amperage x % EFF x power factor x 1.73/746

Where:

Voltage is the average of the three voltages measured: (A-B + A-C + B-C)/3

Amperage is the average current of the three-phase measured: (A+B+C)/3

% EFF is motor efficiency on the motor nameplate

Power factor is the ratio of true power (kW) to apparent power (kVA). If you don’t have power factor measurement tools, estimate the power factor at 0.85.

1.73 is a constant used when calculating three-phase power

746 is the constant for converting watts to horsepower (746 watts = 1 Hp)

Inertia during start-up

Motors at rest require a large force to be set into motion. The force required to overcome inertia brings about a high starting current which can cause overheating. Punch presses, ball mills, crushers, and certain types of pumps require high starting torques due to the considerable weight of the rotating elements.

Special ratings organized into “design types” by NEMA characterize a motor’s ability to endure the heat of that starting and pull-up. NEMA designates these as design types A, B, C, and D. The industry standard is type B which is ideal for most commercial and industrial applications.

Adjust for duty cycle

The duty cycle is the load a motor must endure when it starts, runs, and stops. You’ll need to determine whether the application will be continuous or intermittent.

- Continuous duty: the most straightforward and most efficient application. The duty cycle begins with startup and continues for long periods of steady operation. The heat in the motor can stabilize as it runs so that it can be operated safely at or near rated capacity. Examples include fans, centrifugal pumps, and paper-making machines.

- Intermittent duty: the duty cycle begins with startup, continues for a specific period and is then shut down. It can sufficiently cool if it’s shut down for an extended period. But if it’s shut down for a short period, a sufficient amount of cooling of the motor to the ambient temperature isn’t possible. Examples include cranes, excavators, and lift-hoisting machines.

Consider motor hypoxia

If your motor is going to run at altitudes substantially above sea level, then it will be unable to operate at its full service factor. This deficiency is created because air is less dense and does not cool as well at higher altitudes. So, for motors to stay within the safe limits of temperature rise, they should be rated on a sliding scale:

Up to an altitude of 3,300 ft, S.F. = 1.15

At 9000 ft, S.F. declines to S.F. = 1.00

Need a replacement yesterday?

Let us help.

Determine the size of the motor

Properly sizing a motor for your equipment is critical to ensuring performance and reliability. A lot of times, vendors get calls simply asking for a motor of a specific horsepower. But if a motor is undersized, it won’t be able to control the load. If the motor is oversized, it may handle the load, but it will also be heavier and more expensive in terms of price and operating costs.

Measuring accurately requires knowledge of the details of the mechanical system, the operating parameters, and the circumstances under which the equipment will be used.

Also, think about how much space the motor will take up and how it will be mounted or fixed in the system. You’ll have greater flexibility with the motor’s size and weight if the system is in a designated location. And you can prioritize the performance you need for your application.

Match it with the industrial environment

Luckily there is a format adapted for every industrial environment, including explosive, damp, corrosive, high temperature, and more. For harsh environments, there are motors with waterproof, shock-resistant, and dirt-resistant casings. So, let’s get into the major ones:

General-purpose motors

General-purpose electric motors are sold in a wide range of construction enclosures from industrial steel band open designs to enclosed cast iron designs, and in single and three-phase, for harsh applications.

General-purpose motors can be used in many applications and are typically energy efficient, durable and widely available.

Shop our general-purpose motors with a variety of enclosure types and frame materials.

Explosion-proof motors

Explosion-proof motors are required for industrial applications with highly combustible materials. Contrary to its name, explosion-proof does not mean that the motor will never explode. The product has features to prevent the more significant combustible atmosphere from being ignited by an internal motor explosion.

Motors that are explosion-proof are used in hazardous environments such as oil and gas recovery, chemical and petroleum refineries, and mining.Explosion-proof motors must satisfy U.L. explosion-proof certification, identifiable by a U.L. listing identification plate affixed to the motor enclosure.

Shop our certified

explosion-proof motors.

Severe-duty motors

These motors are designed to provide outstanding performance and long life in harsh environments, such as petrochemical plants, mines, foundries, pulp and paper mills, waste management facilities, rock crushers, and chemical plants.

These motors include features designed to protect against contamination, moisture, vibration, and demanding duty cycles.

Shop our severe-duty motors to handle harsh conditions.

Farm-duty motors

Farm-duty motors are built to perform in the demanding environments of agricultural applications. They are designed with features for rugged conditions and provide the necessary reliability to keep farm operations up and running.

Pump motors

Pump motors are designed for various pump applications such as food processing, washdown applications, or explosion-proof enclosures for pumps in hazardous areas.

Washdown motors

Washdown motors are designed with exceptional features to prevent water damage to the motor. Stainless steel washdown motors are explicitly built for rugged and demanding environments in car washes, food processing, and other industrial settings.

Shop our washdown motors in various designs to fit the needs of many applications.

Metric motors

Metric motors are just motors with an underlying engineering design based on a metric system of units. There are metric dimensions found on various machines, equipment, or tools. Metric motors operate on 50 hertz, which is suitable in most countries outside the U.S. that use 60 hertz.

Oil well pump motors

Oil well pump motors are specifically designed and constructed for all oil well beam pumps. These motors will perform in the harshest environments, guaranteeing the user an extended motor life and cool operating temperatures.

Shop our oil well pump motors for the maximum run time in the harsh environments of oil production.

Definite-purpose motors

Definite-purpose motors are designed to handle various applications with well-established NEMA standards. They can be used for specific applications and are high efficiency and low in cost compared to general-purpose motors with similar ratings. Definite-purpose motors can be used for various purposes and applications in several industries.

Shop our definite-purpose motors now.